DDG(X) Quicklook

faster please

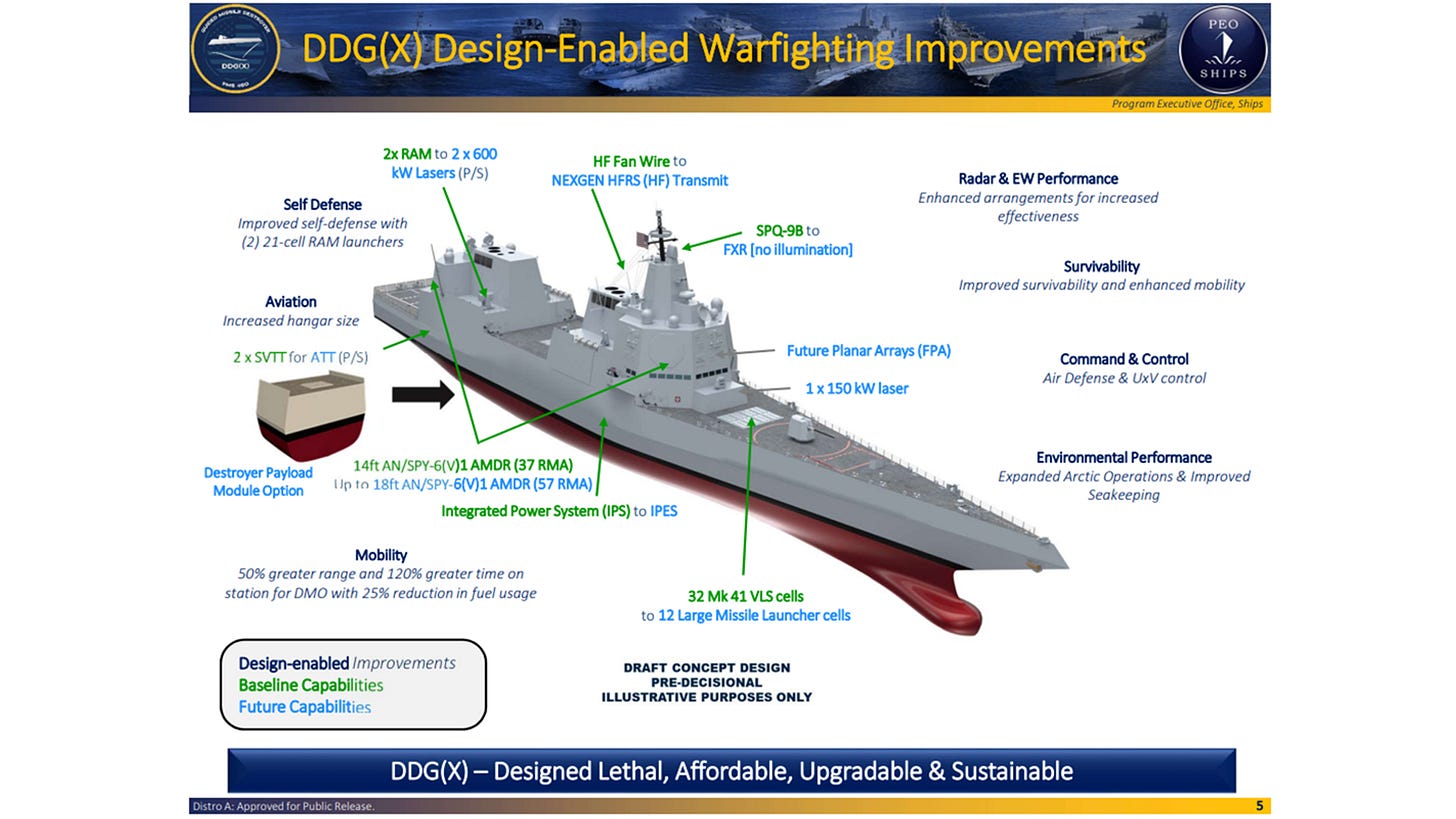

At last week’s SNA, an initial concept for DDG(X) was put up on a slide for all to see;

Don’t get too excited though;

...the hull form shown in the concept image is not representative of the ship and that the service has not settled on a specific design yet.

...

The program office isn’t committed to a specific hull design but presented a swept, angular, bulbous bow design reminiscent of an Arleigh Burke rather than the tumblehome, wave-piercing design of the Zumwalts.

“We haven’t actually locked down the hull form, yet. That’s a concept,” Connelly said, referring to the concept drawing the office presented.

“It is one of the many options still in play. … We as the design team, are going through all the different options to see which one performs best for the long-term and the mission.”

Let me start out with saying what I do like.

First of all, with a focus on fighting in Westpac you need range and dwell time. We seem to have it;

The Navy is also calling for a ship that can travel 50 percent farther ... (than an Arleigh Burke)

Second, after a couple of decades of serial debacles born from the Age of Transformationalism, we need minimal technology risk;

The combat system developed for the Flight III destroyers will be wrapped in a new hull that would be able to grow as weapon systems evolve, Connelly said.

“When we upgraded the Flight III … we took up all of the service life allowance on that platform. All of the space, weight and power has all been allocated. There is not enough room on that ship to put a new combat capability that takes more power or a larger footprint within the ship,” she said.

“The first ship will focus on a new hull form and a new integrated power system. We will use the proven combat system from the Flight III ship so we are designing the ship with the flexibility and the margins to accommodate the future of the Navy and the needs for where we’re going.”

In the spirit of the Spruance Class DD, we seem to be designing the platform with enough white-space so capabilities yet ripe can be included at a later date. The important thing is to displace water with the good now, and then make it better later. Very solid.

I do have some concerns, starting with weaponeering;

Initially, the ship would feature a 32-cell Mk-41 Vertical Launch System forward of the superstructure that could be swapped for 12 larger missile cells capable of fielding the Pentagon’s emerging hypersonic weapons being developed for the Navy, Army and the Air Force.

The current DDG-51s field 96 MK-41 VLS cells and USNI News understands that Navy requirements keep the VLS cells for DDG(X) about the same.

I’m sorry, that simply is not enough VLS cells. Ripping out the 32 so you can put in a dozen hypersonics doesn’t seem all that wise either unless that is a mission swap out you can do from a (yet to be designed and built) destroyer tender. Looking at the slide, I get the aft end is helo country, but what is amidships? Where are the ASCM?

I don't think this part of the show was ready for prime time.

Let's take a look at Ronald O'Rourke's summary in the Congressional Research Service report;

The Navy’s DDG(X) program envisages procuring a class of next-generation guided-missile destroyers (DDGs) to replace the Navy’s Ticonderoga (CG-47) class Aegis cruisers and its older Arleigh Burke DDG-51) class Aegis destroyers. The Navy wants to procure the first DDG(X) in FY2028. The Navy’s proposed FY2022 budget request $121.8 million in research and development funding for the program.

Non-concur here. We are repeating the mistake of trying to have a one-ship-fits-all false economy. Especially with long range hypersonics, we need to have a large surface combatant - yes a cruiser - at least the size of the ZUMWALTS that can carry dozens of hypersonics and still defend itself.

Navy’s General Concept for the Ship

Figure 1 shows a Navy rendering of a notional DDG(X) design concept. The Navy approved the DDG(X)’s top level requirements (i.e., its major required features) in December 2020. The Navy envisages the DDG(X) as having

- an integrated propulsion system (IPS) that incorporates lessons from the DDG-1000 IPS and the Navy’s new Columbia-class ballistic missile submarine;

- initially, combat system equipment similar to that installed on the Flight III DDG-51; and

- more weapon capacity than the Flight III DDG-51.

Navy officials envision the DDG(X) as being larger than the 9,700-ton Flight III DDG-51 design, but smaller than the 15,700-ton DDG-1000 design. A DDG(X) design midway in displacement between the DDG-51 and DDG1000 designs would displace about 12,700 tons, but the DDG(X)’s displacement could turn out to be less than or more than 12,700 tons. The Navy states that the DDG(X) would

integrate non-developmental systems into a new hull design that incorporates platform flexibility and the space, weight, power and cooling (SWAPC) to meet future combatant force capability/system requirements that are not achievable without the new hull design. The DDG(X) platform will have the flexibility to rapidly and affordably upgrade to future warfighting systems when they become available as well as have improved range and fuel efficiency for increased operational flexibility and decreased demand on the logistics force. DDG(X) will provide an Integrated Power System with flexibility to enable fielding of high demand electric weapons, sensor systems and computing resources.

(Source: Department of Defense Fiscal Year (FY) 2022 Budget Estimates, Navy, Justification Book, Volume 2 of 5, Research, Development, Test & Evaluation, Navy, May 2021, p. 479.)

Here's my $.02 … they needed to put something out, so they put something out. Fine. However, we need to be building something. I fear we are stuck in analysis paralysis as we have not even selected a hull form yet?

I’m not running anything, but if I were, I’d simply tell the team, “Pick one by 21 Jan 21 and let’s get moving with the most viable hull form. If the losing hull form in a couple of years looks like a player, then we can build it too as another class. Yes, we can build more than one class of DDG. Other generations did, it worked well for them, we can do it too … but we need to be building now.”

If they are not ready to do that, then fire the entire team and bring in a new one.

Faster please.

Absolutely concur with do it NOW. We used to have a CGX program, but that fell by the wayside for any number of reasons only explainable if you served a tour in DC.

Set a time limit on total design time as well as the final construction deadline. I had the opportunity to work as the Blue Team Design Integration Manager for DDG-1000, and my Ph.D dissertation was on DoD cost overruns, so I think I have some room to speak up on this. The only way to keep displacement and total cost under control is to set requirements that don't violate the laws of physics, provide steady development funding, develop a risk management program that does more than parrot the program manager's personal point of view, and tie total program success to everyone's fitrep.

The wording on the slide is clumsy. The concept image shows 64 cells in the forward block, and a midships block is just visible behind the deckhouse which looks like it may be another 32. The 32-for-12 swap would only affect a portion of the total cells, one presumes.

The meaning of the "payload module" is also not made clear, but the choice of terminology evokes the Virginia Payload Module, which is a hull insert enabling Block V boats to carry 4 additional payload tubes. If this was an intentional reference, and the blue text is taken as "this is something to be added," they may be considering a similar plug as something some (but not all) DDG(X)s could be built with.