A Constellation of Challenges, with Emma Salisbury - on Midrats!

the big risks with great expectations

Look who we have on a short-turnaround visit to Midrats, Dr. Emma Salisbury!

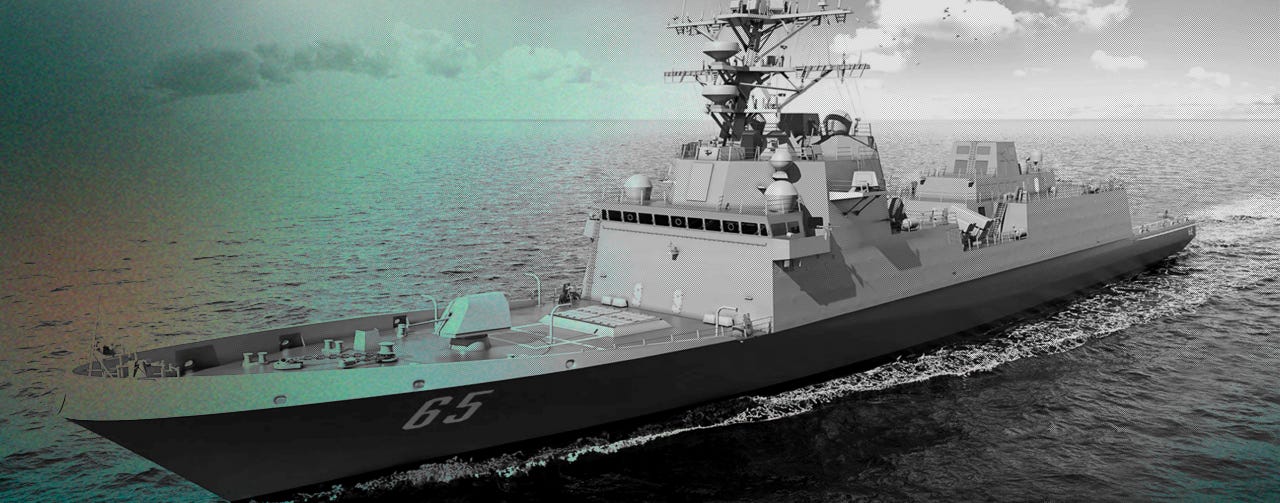

We’re going to cover the waterfront issues in the Anglosphere, but we’ll kick off the discussion with the issues she outlined in her recent Behind the Front post, Franken-FREMM: How the Constellation Class Became a Monster.

Emma recently completed her PhD at Birkbeck College, University of London, with research focusing on the history of the U.S. military-industrial complex. She is the Sea Power Research Fellow at the Council on Geostrategy, Fellow at UK Strategic Command Defence Futures, and an assistant editor at War on the Rocks.

You can listen here, or at the Spotify embed below.

Showlinks

Franken-FREMM: How the Constellation Class Became a Monster - Emma Salisbury

Beyond the Iron Triangle: The Military-Industrial Complex as Assemblage - Emma Salisbury

The US Navy has Fallen Victim to the British Disease - Tom Sharpe

Summary

The conversation discusses the challenges and systemic problems in naval shipbuilding, specifically focusing on the Constellation Class FFG program. The guests highlight the lack of learning from previous failures, the accumulation of unnecessary changes, and the desire for perfection at the outset. They also explore the mindset issue in shipbuilding, the impact of economic considerations on decision-making, and the importance of maintaining shipbuilding capacity. The conversation emphasizes the need for an iterative approach and long-term planning to address these issues. The conversation explores the challenges and issues surrounding naval procurement and shipbuilding in the UK and the US. It discusses the underfunding of the armed forces, the problem of project creep, the need for investment in defense, and the importance of having a clear vision for ship designs. The conversation also touches on the potential of AI and unmanned assets in the future, the need for flexibility in ship designs, and the importance of maintaining a strong defense industrial base.

Takeaways

Naval shipbuilding faces systemic problems and a lack of learning from previous failures.

The desire for perfection at the outset and the accumulation of unnecessary changes contribute to shipbuilding challenges.

Economic considerations and the impact on local communities often influence decision-making in shipbuilding programs.

Maintaining shipbuilding capacity is crucial for national security and requires long-term planning.

An iterative approach, similar to China's shipbuilding strategy, could be beneficial for naval shipbuilding programs. Both the UK and the US have historically underfunded their armed forces, leading to challenges in naval procurement and shipbuilding.

Project creep, the tendency to continuously add features and modifications to a design, has been a major problem in naval procurement.

Investment in defense is necessary to ensure the readiness and capability of armed forces.

There is a need for a clear vision and focus on the intended role and capabilities of ships, rather than trying to make them do everything.

While AI and unmanned assets hold promise for the future, there is still a long way to go in terms of technology development and integration into fleet structures.

Flexibility in ship designs is important to accommodate future upgrades and capabilities.

Maintaining a strong defense industrial base is crucial for national security and the success of naval procurement and shipbuilding.

Chapters

00:00: Introduction

01:21: Systemic Problems in Naval Shipbuilding

03:03: The Constellation Class FFG Program and its Challenges

06:01: The Desire for Perfection and Accumulation of Changes

10:26: The Need for an Iterative Approach in Shipbuilding

17:47: Economic Considerations and Decision-Making in Shipbuilding

22:40: The Importance of Maintaining Shipbuilding Capacity

25:23: Long-Term Planning for Naval Shipbuilding

29:48: Underfunding and Sea Blindness

33:01: The Problem of Project Creep

35:44: The Need for Defense Investment

38:41: Making the Case for Defense Spending

44:12: The Importance of Clear Ship Designs

46:09: The Potential and Limitations of AI and Unmanned Assets

49:32: Flexibility in Ship Designs for Future Upgrades

52:09: The Challenge of Limited Space and Displacement

55:09: Fixing the Defense Industrial Base

I'm not a Navy veteran or naval architect so I can't comment about the ship design features. But I do have expertise in innovation, particularly regarding engineering and technology. The current USN approach to shipbuilding runs completely counter to all lessons about innovation and the Agile Loop, which uses a Model-Build-Lean loop. In simple terms, start with a basic model. Build the first one. Put it in the hands of the professional sailors to see what works, what doesn't and why. Take those insights back to the designers to make modifications, build the second one and repeat. By the 4th or 5th version, you're pretty close to your optimal design. We use this technique every day and it's just the standard approach to technology development.

So why does the Pentagon have such difficulty utilizing this proven method? The Chinese are clearly doing so with great effect. The concerns in the podcast about starting and stopping the production lines are certainly valid but are also easily resolved by instilling this innovation model into the production and evaluation cycle. I consider the shipbuilder's threats about laying off people to be little more than posturing. Many other industries have successfully implemented this innovation model with great success. There is no reason why the shipbuilders cannot do so as well.

So how do you solve this? Is it a political function? If so, does it get handled at the legislative branch when funding is approved or at the executive branch where funding is requested and projects executed? This is a solvable problem and frankly one that can be solved within 2 years if a true innovation model was widely embraced. As a nation, we are setting ourselves up for failure by not doing so.

I think if we had that list we'd understand why the changes are needed. The deception was that the parent design could possibly use American systems and remain remotely similar.

Part of this is deciding the Conops. For an SM-2, 32 cell AAW frigate, we probably decided right in a world where time and numbers don't matter. I think the LCS-1 based frigate based on the ships being built for Saudi Arabia would suck less than commonly understood. Those Saudi ships have the propulsion fix, the chines are gone, the stabilizers are back (I think), adds a bow thruster, larger crew, heavier hull, likely larger range at what would still be a very slow cruise speed on diesels. As an ESSM level combatant we could have had 2 of them per year happening much sooner.

Good point on the type 26 being a better fit. Connie uses the exact same gensets.

Agreed, unmanned is not there yet. Our human timeline to solve it is what is off. 10-11 years and we will wonder how we ever thought it would take 20 years.