We probably need to start this out by explaining exactly what a blast furnace is and why it is important if you want to be a sovereign nation.

First of all, what it does;

The purpose of blast furnace is to chemically reduce and physically convert iron oxide into liquid iron called “hot metal” The blast furnace is a huge, steel stack lined with refractory brick where iron ore, coke and limestone are charged into the top and preheated air is blown into the bottom. The raw materials require 6 to 8 hours to descend to the bottom of the furnace where they become the final product of liquid slag and liquid iron. These liquid products are drained from the furnace at regular intervals. The hot air that was blown into the bottom of the surface ascends to the top in 6 to 8 seconds after going through numerous chemical reactions. Once the blast furnace is started it continuously runs for four to ten years with only short stops to perform planned maintenance.

Why are blast furnaces so important? Remember the middle part of Billy Joel’s “Iron, coke, chromium steel?”

“Coke” is in essence purified coal, almost pure carbon. It is about the only thing that can at scale make “new” or raw iron, aka “pig iron.” Only coke in a blast furnace can make enough heat to turn iron ore in to iron. You can’t get that heat with an electric furnace.

Pig iron is the foundation of everything that follows that makes an industrial power. If you cannot make your own pig iron, you are just LARP'n as a real power.

It takes a semester at least to understand this, but here is all you really need to know;

Primary differences

While the end product from each of these is comparable, there are clearly differences between their capabilities and process. Comparing each type of furnace, the major distinctions are:

Material source – blast furnaces can melt raw iron ore as well as recycled metal, while electric arc furnaces only melt recycled or scrap metal.

Power supply – blast furnaces primarily use coke to supply the energy needed to heat up the metal, while EAFs use electricity to accomplish this.

Environmental impact – because of the fuels used for each, EAFs can produce up to 85% less carbon dioxide than blast furnaces.

Cost – EAFs cost less than blast furnaces and take up less space in a factory.

Efficiency – EAFs also reach higher temperatures much faster and can melt and produce products more quickly, as well as having more precise control over the temperature compared to blast furnaces.

We’ll get to that environmental impact later, but the “Material source” section is your money quote.

Without a blast furnace, all you can do is recycle scrap iron.

You cannot fight wars at scale if all you have is scrap iron. You cannot be an industrial hub off of just scrap iron. If you are a nation of any size, you then become economically and security vulnerable at an existential level. I don’t care how much science fiction you get nakid and roll in; wars are won by steel, ungodly amounts of steel.

Where do you get the steel to build your warships? Your tanks? Your factories? Your buildings? Your factories?

If you can only use scrap, then you are simply a scavenger living off the hard work of previous generations. Eventually you run out. You will wind up like the cypress mills of old Florida where, once they ran out of cypress trees, they simply sold off the cypress lumber their mills were constructed of … and then went bankrupt.

Or … you could import the pig iron - that bad marketing term for the foundation of everything. Who will be making that pig iron and where? (we’ll cover that later down post). How will it get to you?

You can’t fly in pig iron. The UK is an island nation. That pig iron will have to come in by that little tunnel, or by ship.

Same for the worse problem; having to import the finished product. You go broke even faster that way.

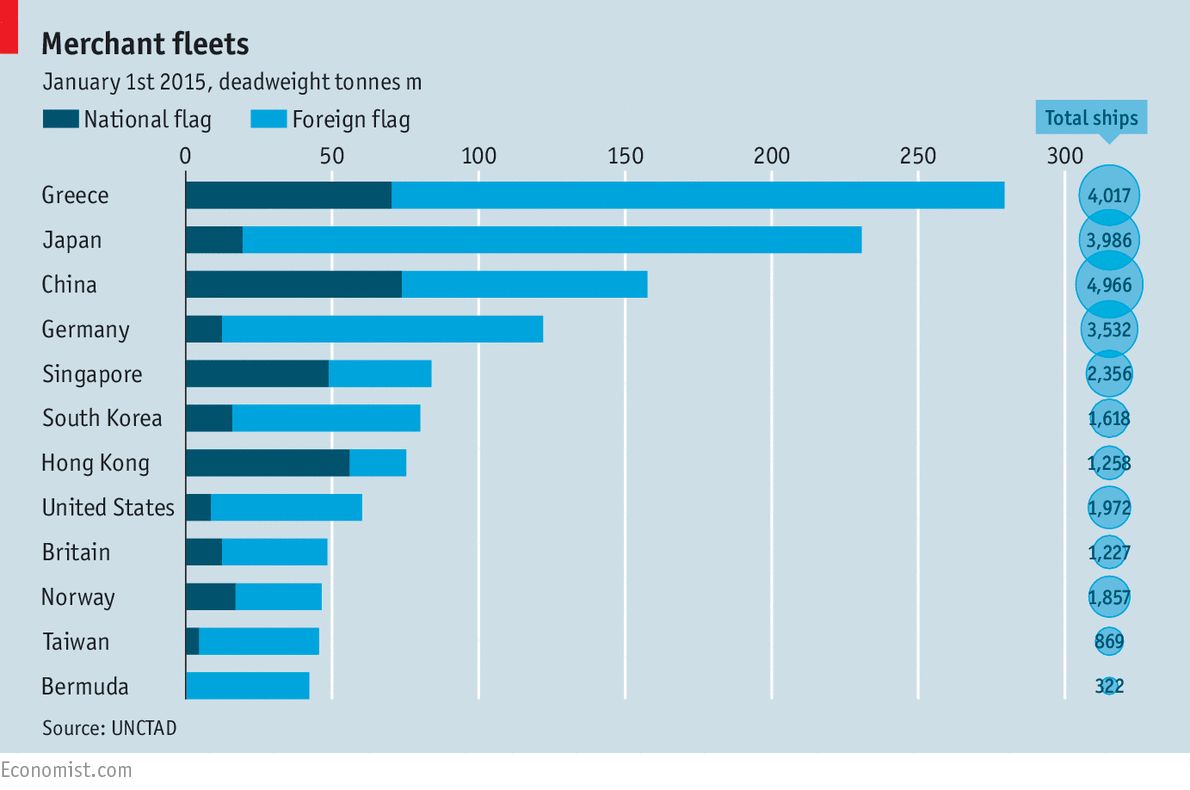

Of course, the merchant ship. Ah, yes, that ship. Who owns that ship? What navy will secure the seas that the ship will go through?

What is the condition of the British merchant fleet? How is the Royal Navy? Those are posts for a different day - but let’s just say that myopia and green eyeshade capitalism has done a number on them as well.

So, with the table set, let’s dive in to the United Kingdom and British Steel.

This is quite the journey for the nation that is pretty much credited with starting the industrial revolution.

There are a lot of ruin in a nation, especially an industrial nation with a lot of human, social, and real capital … but new generations can only feed off the hard work of previous generations for so long. The music stops at some point.

After being the solid rock that led to two victories in sequential World Wars, the UK went through spasms of nationalization, re-privatizations, consolidations, socialism, capitalism, irresponsible unions, hedge funds vulture capitalism, and finally Chinese predatory strategic positioning.

PhD's have already been earned by the scores looking at all these causes, and more will follow - but it didn’t have to end this way.

British Steel to shut down blast furnaces at Scunthorpe plant 'leaving 2,000 jobs at risk'

The company says its plans are essential if the business is to return to profitability but unions say the loss of industrial grade steel in the UK leaves the country at the mercy of imports.

Judas Priest could not be reached for comment, but I have a few more.

British Steel has revealed a decarbonisation plan … Replacing them would be two cheaper, greener electric arc furnaces (EAFs) - one in Scunthorpe and the other on Teesside, where it has two existing mills.

Teesside lost its main steelworks in 2015 when the Redcar plant was mothballed with the loss of 1,700 jobs.

Jingye Group said its plans were aimed at making UK-produced steel competitive again and creating a sustainable future for the business.

While it did not put a figure on the number of jobs to be lost ahead of talks with unions, the company has long argued that high energy and labour costs are a barrier to profitability.

It said that the proposed £1.25bn investment was subject to a government grant, understood to be worth £300m.

The company argued that its plans would reduce British Steel's carbon dioxide emissions by 75% as EAFs can run on zero-carbon electricity.

Let’s pick this apart:

Decarbonization/Green: this is just greenwashing mated with gaslighting. Pig iron will be made somewhere on this planet where we all share the same air and water. A modern, properly regulated blast furnace in the UK will produce orders of magnitude less “carbon” and toxic pollution than something in the PRC or India. Everyone knowledgeable knows this, but the grasping people of ill-will relies on the ignorance of the people and pliable - and buyable - press and politicians.

Electric: electric power is mostly produced from hydrocarbons and, as we noted above, is not a substitute for a coke powered blast furnace. Industry know that, but is lying to you hoping you won’t know the difference in shifting the “carbon” from one industry to another. If you’ve read this far, congratulations, you have now joined the 0.5% of people who do.

Jingye Group …who are they and how did they get there? Well, we have a story to tell.

This link is quite useful to get the amazingly chaotic history of British Steel starting with the orgy of socialist nationalism and the reaction to it after WWII all the way to where we’ll pick up the story in 2007 when Anglo-Dutch Tata acquired it for ~$13 billion.

By 2016, British Steel found itself bought for - literally - pocket change by the vulture-capitalist hedge fund…excuse me “LLP investment company” Greybull Capital.

This version of British Steel was six-sigma’d in to insolvency by 2019.

That is when the Jingye Group swept in to buy British Steel for £70 million. By then, UK steel manufacturing employment fell from 300,000 in 1971 to 10,000 in 2019.

Jingye Group, China's leading steelmaker and multinational conglomerate, acquired British Steel in March 2020 and started a new era in British steelmaking.

Jingye Group was founded in 1990, and its headquarters are located in Shijiazhuang, China.

As a leading steelmaker, Jingye's affiliates also include Jingye Steel, Ulanhot Steel, Yunnan Jingye Steel and Guangdong Jingye Steel.

…

Jingye Group employs a global business strategy, supplying steel and metal products and associated services. It has affiliates in 22 countries and exports its products to more than 80 countries and regions.

Ah yes, selling the rope to hang that hangs you.

Do you see it now? It is, was, and will be right there.

Would the PRC let a foreign power with a grudge do this to such a strategic industry there?

No, of course not.

The UK is the USA’s most consistent and reliable partner in world security. Especially her military - when she is strong, we are strong. When she is weak, we are probably alone.

Blast furnaces matter. Industrial Britain is an American national security concern.

Hey, while we are at it, let’s look where are the world’s blast furnaces are.

Does that sober you up?

The global free market is not free and is not a market. The PRC is not a capitalist state. The PRC is a growing power with imperial ambitions. We are decades past the Cold War delusions that history has ended and we can all just watch our stock portfolios prosper while we nap in a globalist utopia.

Why does this matter to the USA and the West? I don’t have to answer that question, do I?

Never forget, those who claim they are The Smartest People in the Room™ aren’t. The best and the brightest in the West - arrogant, entitled, blinkered and grasping - have brought us here. Few will be able to bring us out. We need new people, from different backgrounds - and nothing to make excuses for.

Time is not our friend.

Sal, this is one of your most prescient blog posts you've made. After I retired from the USN I joined a start-up company working on water quality monitoring "in situ" - which was huge since you could measure water quality in the pipe and did not have to draw out a sample to test. I finalized the development, received 3 patents and into business we went. We made our kit from 316L stainless steel, and used a shop in Sheffield UK to make the probes, and it was great. Chinese "316L" steel rusted in 3 months. Sheffield in decades. In 2005 we were notified that the stainless steel company was being bought by a Chinese firm. 38 days later I received a call at an hour well past business hours from a Chinese company wanting to buy ONE of our $10,000 probes. I politely declined, and the voice on the other end said "we will buy all your suppliers to get your intellectual property". I had just finished negotiations with Israel on installing the monitoring equipment in all their overseas embassies since the Italian police had discovered 3 PALESTINIANS attempting to drill into the water main feeding the Israeli embassy in Rome. Management thought a Chink buy-out a great idea. I politely reminded them I had the patents in my name. I left and started my IT business. The Chinese will win since American business thinks "cash over nation".

Taking this with yesterday's post on the newest Chinese massive seaport and drydock in CAMBODIA should be a huge wake up to anyone paying attention to this century's "Great Game."

China thinks and plans for the long term, (decades or centuries) with national strategic interests at the core of its decision making. Commercial decisions are driven by, or at least linked to and supportive of, national interests.

American decision making is driven by hoping to win the next two year or four year election cycle by passing out "free stuff" or tugging on emotions to assuage hurt feelings or guilt over suffering somewhere and squandering billions of dollars on nations who hate us. Very damn few of the oppressed people or evil oppressors around the world are a vital U.S. national interest. And very few will be rescued regardless of how much American blood or treasure is expended to civilize people who do not want to be civilized.

Economic actions can be as decisive as military actions, and the self inflicted idiotic obsession with "green" and other environmental crap will bring us to our knees and destroy our nation just as surely as if military strikes wiped out our basic infrastructure in an EMP attack.

The enemy is not just outside the gates, but barricaded in our education establishment, the media, and concentrated in one political party condemning our culture, traditions, economy, and religions. They are successfully imposing self loathing, Marxism, anarchy, class warfare, anti-militarism, depraved notions of sexuality, and socialistic destruction of the means of production under the pretext of some sort of environmental miracle cure to counter the fluctuations of climate and weather.

I see nothing to indicate that China will not replace the U.S. as the dominant world power within the next five to ten years. The recent double downgrade of the U.S. dollar and inevitable rise in interest costs may cause our collapse even sooner.

"A republic, if you can keep it," indeed.